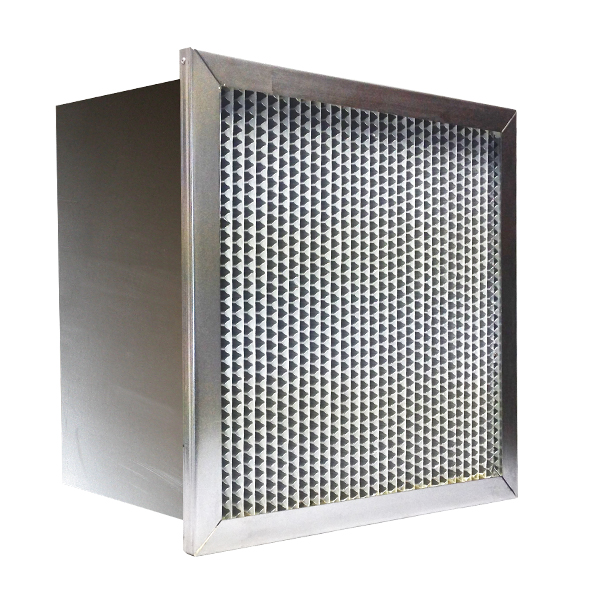

HEPA filters are designed to arrest very fine particles effectively, but they do not filter out gasses and odor molecules. Circumstances requiring filtration of volatile organic compounds, chemical vapors, cigarette, pet, and/or flatulence odors call for the use of an activated carbon (charcoal) or other type of filter instead of or in addition to a HEPA filter.

HEPA filters are composed of a mat of randomly arranged fibres. The fibres are typically composed of fiberglass and possess diameters between 0.5 and 2.0 micrometres.

Key factors affecting its functions are fibre diameter, filter thickness, and face velocity. The air space between HEPA filter fibres is typically much greater than 0.3 μm.

HEPA filters are designed to target much smaller pollutants and particles. These particles are trapped (they stick to a fibre) through a combination of the following three mechanisms:

Interception

where particles following a line of flow in the air stream come within one radius of a fibre and adhere to it.

Impaction

where larger particles are unable to avoid fibres by following the curving contours of the air stream and are forced to embed in one of them directly; this effect increases with diminishing fibre separation and higher air flow velocity.

Diffusion

an enhancing mechanism that is a result of the collision with gas molecules by the smallest particles, especially those below 0.1 µm in diameter, which are thereby impeded and delayed in their path through the filter; this behaviour is similar to Brownian motion and raises the probability that a particle will be stopped by either of the two mechanisms above; this mechanism becomes dominant at lower air flow velocities.

Diffusion predominates below the 0.1 μm diameter particle size. Impaction and interception predominate above 0.4 μm. [6] In between, near the most penetrating particle size (MPPS) 0.21 μm, both diffusion and interception are comparatively inefficient.